PET Sheet Extrusion: A Revolutionary Process in Sheet Extrusion

In today's fast-paced world, sheet extrusion has become an integral part of the manufacturing process for a wide variety of applications. Sheet extrusion lines are utilized in the production of plastic sheets for various consumer and industrial products. The sheet extrusion process is a modern technology that transforms raw materials into polymer sheets of different sizes and shapes, capable of fulfilling the specific requirements of customers.

The world-renowned Sheet Extrusion Manufacturers today have taken the sheet extrusion process to the next level, introducing cutting-edge technologies in PET sheet extrusion. PET Sheet Extrusion is a groundbreaking process that is transforming the plastic sheet extrusion industry.

What is PET Sheet Extrusion?

PET is an acronym for Polyethylene Terephthalate; it is a type of thermoplastic polymer resin commonly used in plastic products like soft drinks, water bottles, food storage containers, and more. PET sheet extrusion is the process of manufacturing plastic sheets from PET materials.

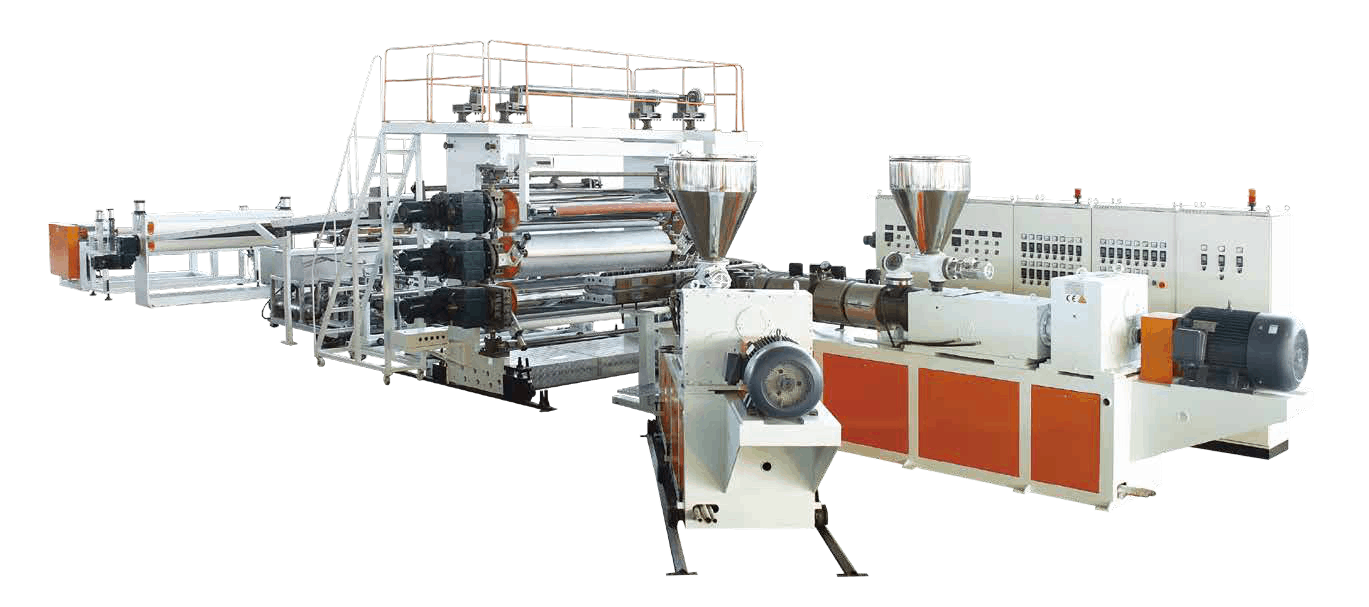

PET sheet extrusion utilizes a series of industrial machines that process PET pellets or PET resin into plastic sheets of different thicknesses, widths, and lengths. The process involves heating the PET material to a melting point and then using an extruder machine to force the molten PET through a die or series of dies that shape the material into flat sheets.

Once the sheets have been extruded, they can be modified in different ways and cut to the required size for specific applications.

Why Choose PET Sheet Extrusion?

PET Sheets are known for their excellent thermal, mechanical, and chemical properties, thus making them ideal for a wide range of applications. PET Sheet Extrusion is beneficial for several reasons:

- High Durability: PET is a strong, durable, and lightweight material, making it perfect for various applications.

- Heat Resistance: PET sheets are resistant to heat and can withstand temperatures over 300 °F.

- Chemical Resistance: PET sheets have excellent resistance to chemicals, solvents, and oils.

- Recyclability: PET is a widely recyclable material with an impressive environmental footprint.

- Cost-Effective: PET sheet extrusion is a cost-effective solution for manufacturing high-quality plastic sheets.

Conclusion

The PET Sheet Extrusion process is an innovative and cutting-edge technology that has transformed the plastic sheet extrusion industry. With the innovative technology and expertise of Sheet Extrusion Manufacturers, PET sheet extrusion lines have become more efficient, productive, and environmentally friendly.

Pet Sheet Extrusion Line, Plastic Sheet Extrusion, Plastic Sheet Extruder Manufacturers, PVC Sheet Machine, PP Sheet Extrusion Line, and PVC Sheet Extrusion Line are some of the popular sheet extrusion technologies utilized in manufacturing plastic sheets. Whether you require plastic sheets for packaging, printing, or any other application, PET Sheet Extrusion is the future-proof solution for all your sheet extrusion requirements.